The characteristics of raw hides vary depending not only on the type of animal but also on the place of origin.

Even if they are tanned the same way, the finish will be different.

It is important to listen to the voice of the leather and create items by tanning and finishing that are suitable for the leather, rather than saying which production areas are bad.

What BONCOURA values is harmony and balance.

Making clothes is similar to cooking, and there are certain things that are important in order to make the best products.

For example, if you make miso soup using the highest quality miso and the highest quality caviar, it may be delicious to some extent, and it may be possible to make the best of them, but if you ask me whether it can be called the best dish, I still have doubts.

Also, if you're making miso soup, it's cheaper than caviar, and you can make it more delicious by using other ingredients, and there are even more delicious ways to eat caviar.

The optimal cooking methods and dishes differ depending on the material.

In addition, raw ham melons are a little less sweet and the flesh is a little firmer than Japan's high-quality sweet, soft, and juicy melons, which have a better balance of sweetness, saltiness, and texture.

In this way, I don't necessarily think that the more expensive the material is, the more important it is to have balance and harmony.

Similarly, when it comes to clothes, it doesn't mean that the more expensive the material, the better.If the direction is not aligned, the true value of the material cannot be demonstrated, and even if you can make the best clothes using that material. We also believe that it is not the best one.

However, the harmony and balance that we aim to create is extremely difficult to put into words, so it can only be explained in abstract expressions, but those who like objects and materials will appreciate the harmony. We believe that the quality of the product is one that you can be satisfied with.

We continue to study and update every day to create things that move the heart.

There are many techniques in addition to the commonly known normal process of tanning leather.

I can't go into too much detail.

Each tanner has a secret recipe.

Also, each tanner has their own strengths and weaknesses, and this is because the chemicals, water, and processes used are slightly different.

In order to create the leather that BONCOURA is looking for, we choose the tanner who is best at making the leather, and we tour the factories ourselves to make the most suitable leather at that time.

In addition, when it comes to raw hides, we select high-quality ones with as few scratches as possible.

As the quality of raw hides deteriorates year by year, it is difficult to continue to obtain clean hides, and this is only possible because we have a direct relationship with the tanner and have a relationship of trust.

Impressive appearance and changes over time

And above all, place importance on the feeling of contact with your fingertips.

We continue to make leather.

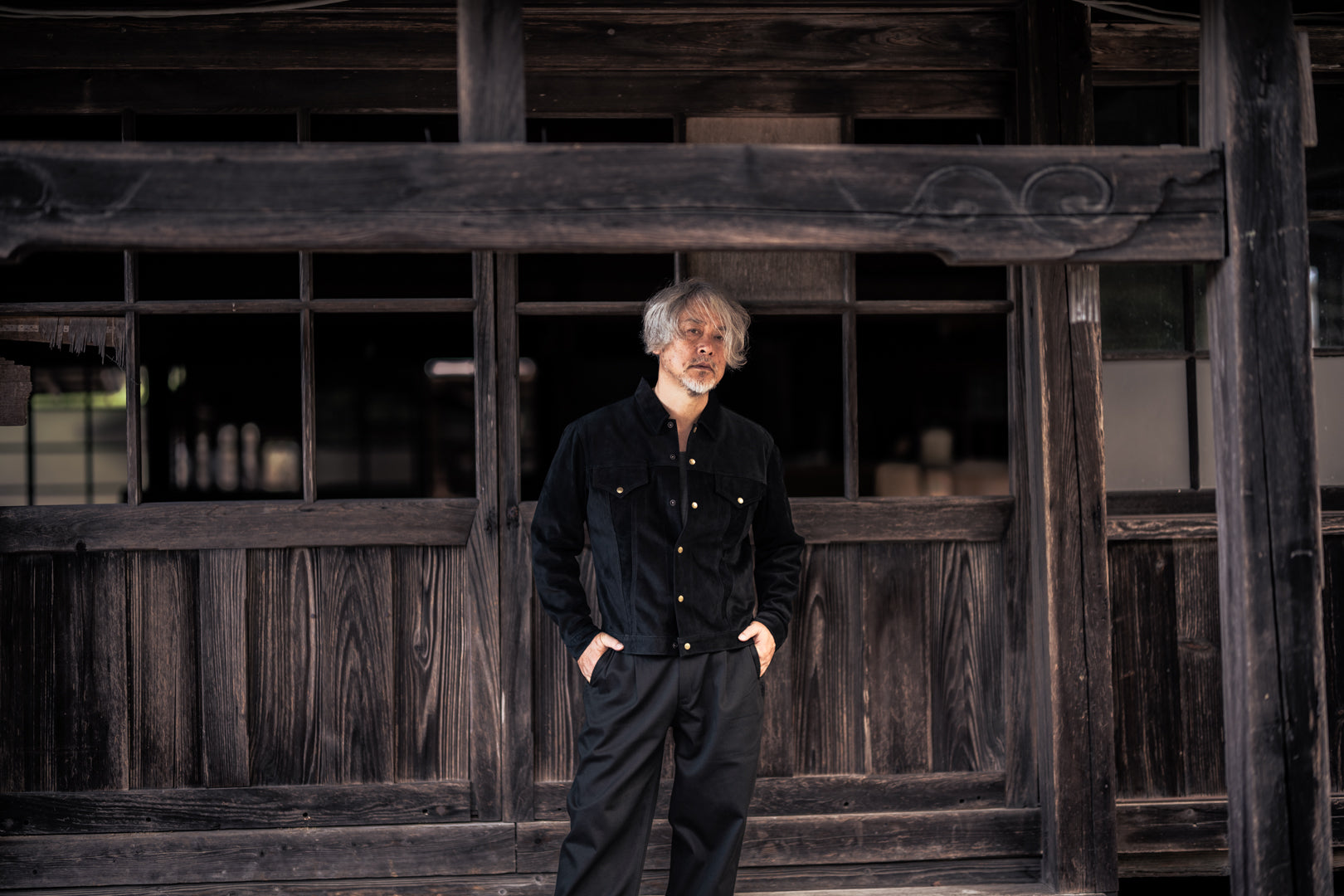

BONCOURA leather jacket eldest son

3rd Denim Jacket with a beautiful silhouette that BONCOURA is proud of.

The secret to her beauty lies in her slightly slender and sophisticated shape.

It is possible to use the pattern for leather as is, but to make the most of the characteristics of the leather and coordination, we create a new pattern from scratch and adjust the size so as not to impair the beauty of the original silhouette of the shirt. Not only that, but you can also layer thin knits and other items.

It is made from one piece without lining, so please enjoy the high quality and smooth texture of the inner silver surface.

The biggest feature of this leather is that it repels water.

Normally, when you think of making suede water resistant, you think of waterproofing spray, but since waterproofing spray coats the leather surface, the texture will not feel like the original leather, but instead will feel like the waterproofing spray.

Therefore, with the cooperation of skilled craftsmen, BONCOURA has developed a new leather that is smooth, elegant, and can be enjoyed with age through trial and error.

The special tanning process prevents color bleeding and stains caused by water, which is suede's biggest weakness, so you can grow it without worrying about it even on rainy days.

Also, wrinkles on the elbows and other wrinkles appear every time you wear it.

The SASHA Jacket, which is the second generation of smooth leather following the BONCOURA suede jacket, has a tea core inside, making it very enjoyable to age.

The concept was to create a leather jacket that is neither too heavy nor too light, that will change over time, and that you can wear without worrying.

The item I was inspired by was a tailored jacket from the 30s, which was originally a tailored jacket, but I knew that tailored jackets were weak in strength and wouldn't be able to withstand hard use, so I changed the lining and other specifications. I finished it in a good shape.

In terms of size, most common leather jackets tend to be tight-fitting, perhaps to reduce the consumption of leather, and are often unsuitable for layering as they lack a wide range of coordination.

BONCOURA wanted to create a leather jacket that could be layered more casually and expand the range of coordination, so this item was created.

Vintage leather jackets are often relatively hard and heavy, and to be honest, unless you put effort into aging them, your arms won't bend and your shoulders will get stiff, which makes them look impressive, but today I'm going to wear a leather jacket! There are many things that you can't wear unless you put effort into them, and on the other hand, if you gradually reduce the thickness, you can make them lighter.

It becomes more like a cloth with a leather texture than leather, and it loses its quality as a leather.

Also, the thinner it is, the more restrictions there are on tanning.

It was very difficult to balance the conflicting qualities of leather, such as being too heavy, soft, fleshy, and textured, and we had to recreate the samples many times.

Generally, when manufacturers handle leather for clothing, they simply ask a leather wholesaler for the leather for clothing, and then use tanners' know-how and recipes to change the finish.

This is because developing a tanning method from scratch is extremely difficult.

After making many prototypes, I realized that even if you were able to make leather that you thought was good after it was tanned and finished, when you actually tried sewing it, you would find that due to the characteristics of the leather, it would not be possible to sew it into clothing. There was also.

Dozens of pieces of leather were tanned to create the sample.

After many trial productions, the resulting leather is soft, supple, and not too thin, which is what BONCOURA is looking for.

In order to have a darker surface color than the SASHA Jacket and a more moist and rich feel in the hand, we have made the skin a little thicker and added more oil.

Inspired by the 1930s Car Coat

The model modified with BONCOURA's interpretation combines ruggedness and masculinity.

The nut buttons are also shaped from vintage pellets from 50 years ago and dyed using traditional methods.The more you use these buttons, the more their color will change over time.

lining

You can often find wool items in vintage clothing, but although wool has excellent heat retention, it can only be worn in the middle of winter, and things you wear inside tend to get caught, so people tend to wear them with great enthusiasm. Masu.

If you want something other than wool, you could use cotton flannel, but if you want it to be as thick as leather, you'll need a certain thickness, so if you do that, you won't be able to wear it again for a long time, so I decided to put flannel on hold.

That's when I thought of Cupra.

Although it is rare, it has a history of being used in vintage leather jackets, and is an excellent material considering its functionality, such as the feel when worn and the ease with which the sleeves can be threaded.

However, Cupra has one weakness: it is slightly susceptible to friction.

Even vintage items can often be found with frayed hems, which give the impression that they are a little weaker than flannel fabric.

Cupro fabric itself is used as a lining for tailored jackets, etc., and in addition to the characteristics of the fabric, one possible reason is that it is often relatively thin.

Will it be able to withstand the hard use of leather? If cupra that thick doesn't exist, you can make it.

So, in order to make a cupro with a thickness that has never been seen before, we went to a number of craftsmen and were able to create the thickest cupro we had ever seen.

Cupra has a logo that is proof of the original fabric, and is the best lining with attention to the color and weave of the lining.

Leather Jacket 1st

新たな素材馬革を採用したジャケット馬革は牛革と比べ、滑らかで、繊維が細かく柔らかい、

シボや立体感、力強さは牛革に軍配があがるものの、馬革の繊細で滑らかな質感は表情の自然な筋やシワが表情豊かに現れます。

また、部位によっては細かな線が浮かび、牛革と同じく着用者ごとの個性が出やすいのが特徴です。

鞣し

伝統的な植物タンニンを使用。時間をかけてじっくりと風合いを深め、革本来の個性を引き出します。

茶芯仕上げも、着色による茶芯仕上げではなく、タンニン本来の色合いで、使い込むほどに表面の色と内側の飴色が混ざり合う、奥行きある表情に育っていきます。

タンニンの種類や配合まで独自に指定し、何度も試作を重ねて完成させたオリジナルの鞣し。

表面のフェードと内側の焼けによる、二重のエイジングが楽しめる仕上がりです。

BONCOURA 1stをベースにレザー用に再構築。

胸ポケットのフラップを省き、大戦期のディテールを取り入れつつ、あえて5つボタンとすることで、ボタンを留めた際の美しいシルエットを実現しています。

背面はTバック仕様。リベットやフロントボタン、シンチバックまで、金属パーツはすべてBONCOURAオリジナル。銅製リベットには使い込むごとに色が変化し、ボタンやバックルも独特の艶や深みを増していきます。

裏地には、レザー用に開発した肉厚のキュプラを採用。しなやかな手触りと袖通しの良さに加え、ウールを使わないことで長い着用期間とさわかやな着心地を楽しめる仕様です。

BONCOURA belts are made from carefully selected 4mm thick leather.

Basically, the thickness of raw hides varies depending on the part, and if you want to get 4mm ones, the thinnest part must be 4mm.

This is at the level of looking at 100 pieces and seeing if there are a few, and if the silver surface is even more beautiful, the number will be even smaller.

The production area is a secret, but the ones from this area have a solid silver surface and are perfect for belts.

Tanning is a traditional method of pit tanning.In pit tanning, the hide is tanned by gradually soaking it in a tank of thin tannin and then a tank of thick tannin over time.

This method takes a very long time to tan and also requires space.

Leather that can only be obtained through this tanning process is created.

The good thing about this tanning is that the silver surface does not easily fade.

In tanning that uses a general drum, the leather and chemicals are mixed together like in a drum-type washing machine, so the fibers are loosened, but in pit tanning, the raw leather is soaked in the tanning tank as it is, so the fibers are firm. The state will be maintained.

It can be said that tanning brings out the original goodness of the leather to its fullest extent.

Therefore, on the other hand, if you do too much work on the finish, it may cause the silver to float or change over time, which will negate the benefits of tanning in a pit tank, so don't do too much work. This is not a good idea, but if you don't modify it, it will end up being the same as regular pitted leather, so it can be said that it is a material that is very difficult to bring out its characteristics and individuality.

Also, when making a prototype, it takes 2 months for tanning, 1 month for samples, and at least 3 months to check the aging process, and the process of making the belt and aging it is limited to twice a year, so it takes a long time to complete the product. took a very long time.

The leather of the belt has a brown core, and the more you use it, the more the dye on the inside and surface becomes thinner, and the brown tannin color comes out from inside.

I believe that over time, the aging and texture of the leather has become the best belt leather that BONCOURA is looking for.

I came up with the design of the buckle keeping in mind that it doesn't exist.

In order to bring out the simplicity and robustness typical of BONCOURA, use thick lines rather than thin lines. However, if the lines are too rugged, it will look hippie or western, and the places where you can use it as a coordination will be limited.

I wanted to create something that wasn't too overdone and had an unusual impact, so before I asked a craftsman to make a prototype, I reshaped it and made several samples myself, and had the craftsman dig it based on those samples.

The material is made of brass, and the more you use it, the dullness typical of brass will appear and age together with the leather.

The prototype was carved by hand by a craftsman, and the B stamp on the back was engraved by making minor adjustments to the angle and placement many times.

The completed belt buckle has an exquisitely balanced shape and weight, and while it has a strong presence when worn, it has no quirks and is a uniquely balanced buckle.

until it becomes a belt

There are many processes involved in making the belt, including the highly manual part-leather cutting, hole punching, sewing, and edge coating.

Above all, the stitching is hand stitched instead of machine stitched.

The shape of the stitching is invisible when the belt is worn, but becomes visible when the belt is removed or hung.

The shape of the stitches is limited, and the thickness of the needle and thread are unique to hand-stitching, which makes the belt even more appealing.